Sunday, January 2, 2011

2-tube regenerative receiver

The design is by David Newkirk WJ1Z and appears in the September 1992 QST and in the ARRL book "QRP Power". I used the suggested method of obtaining B+ by connecting a couple of 240 to 24 VAC transformers back to back. This gave me 120 volts to 12 volts and back to 120 volts, but now isolated from ground (house system neutral), which is why you do this. I wound up with 110 VDC B+, a little low because my transfomers designed for 240 VAC but used at 120 VAC have more impedance than a 120 VAC transformer would. No big deal. Also the clever regulator using a neon bulb wouldn't work because it doesn't fire that low. But I found that it wasn't needed as my voltage was steady. I used a separate 120 to 12 volt transformer for the filaments.

I didn't make many changes from the design of the article, the main one change being the tuning range. The design is for about a 2 MHz range to include some SW BC plus 40 meters. I wasn't interested in SW BC and wanted the better tuning rate and better stability I'd get by restricting the range. I changed the frequency determining capacitors to give me a range of 6900 kHz to 7350 kHz. The main tuning is reasonably smooth and the fine / bandspread tuning allows getting the desired note on CW and tuning in understandable SSB.

The claims made in the article proved to be accurate. I don't see any hand capacity effects and the regeneration control is smooth. There's a little more stuff to fiddle with, but really the use of this receiver is not much more fussy than that of the S-40A sitting behind it as I write this. The RF attenuator at the input is quite useful when overly strong signals tend to make the signal "tear" or "block", if you know what I mean. Just back off on the RF control and everything is fine again. I find that I can pretty much "set and forget" the regen control, although optimizing for selectivity and sensitivity might be useful for weak signal work.

I built the receiver on a big chassis to give me plenty of room and I'm glad I did that. I did have some issues with stability and microphonics initially, before I narrowed the tuning range. I also put the tank toroid and several associated capacitors on a perf board and rigidly mounted it, plus made some connecting wiring in the frequency determining areas more heavy and provided more sturdy mounting points. Also "potted" the toroid with hot glue. All that helped a great deal.

I considered adding another tube so I'd have enough audio to drive a speaker. But it drives my modern low-Z phones really well and if I want a speaker, I plug in some totally incongruous little powered MP3 / cell phone speakers by LG which do a great job.

The white triangles around the main tuning knob indicate 50 kHz steps from 7000 up. I've replaced them with slightly less ugly but definitely less ambiguous labels showing 50 kHz points from 7000 through 7250 kHz.

There you have it - another project to check off my list: a tube type, good performing regenerative receiver.

Nick, WA5BDU

January 2, 2011

I got an actual comment (!) suggesting a photo of the wiring under the chassis would be useful. I'd considered that initially and now I'm going to add one-

There you have it. Of interest, I think is the little perf board left of the fine tuning capacitor. I added this to stabilize things. It's mounted solidly with four standoffs, not something I'd normally do. It contains the toroid and several frequency range setting caps including one trimmer. Note heavy wire leaving this board to solid tie points also added in the interest of stability. The main tuning capacitor is smaller than the one for fine tuning and is visible above the perf board.

Otherwise, the schematic was interesting with it's use of multiple stages of R-C filtering in the B+ and screen voltage sections. So you see lots of electrolytics. Center left is the "70 volt" audio transformer used to match audio amplifier section down to modern, relatively low impedance phones or earbuds. In the lower right corner is the input or antenna trimmer capacitor and its associated ferrite toroid inductor just inward from it. The capacitor is screw adjusted from the top side through a hole. It's pretty much set and forget though, so didn't need to be accessible.

Thursday, April 22, 2010

RF output current meter for QRP TX

Saturday, March 27, 2010

Measuring high resistances with a MOSFET

Anyway, it put me in mind of an experiment I'd done a while ago to measure how long a capacitor could hold a charge. With a high quality capacitor it's difficult to do because a typical 10 M-ohm voltmeter will drain the voltage off in short order. So the trick is to connect the capacitor to the gate of a MOSFET, which has extremely high resistance, and charge the capacitor and put the voltmeter on the drain side of the MOSFET.

The effect on the drain circuit is hardly linear, but there's a sharp transition where the MOSFET comes out of saturation as the capacitor eventually charges toward zero volts. You can measure that transition gate voltage before hand and when the drain voltage rises to a certain reference point, you're there.

I was surprised at how long a certain film (I think) 0.22 uF capacitor held a charge. It had gone about four days when I accidentally discharged it, so even now I'm not sure. After that I tried an ordinary 0.1 uf ceramic disk and it held its charge for two days.

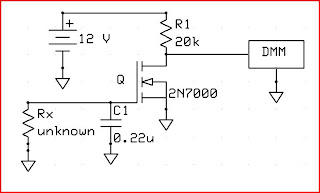

OK, so I know the self-discharge rate of the 0.22 uF capacitor was very slow, so I could use it to test large resistances and assume essentially all of the discharge was due to the external resistance. My circuit is simple enough to describe in words. A resistor, say 20k, from +12.7 VDC battery to the drain of the 2N7000 MOSFET. The source goes to ground. The gate goes to the capacitor and the other end of the capacitor goes to ground. The external resistance being "measured" goes from gate to ground, in parallel with the capacitor.

The MOSFET's channel is ON when the gate voltage goes positive and OFF when gate voltage is zero. So I measured that from a range of 10 V to about 2.25 V gate voltage, the MOSFET was fully on and drain voltage was near zero. Below 2.25 V gate voltage, the drain voltage started to rise and was at 8 V with 1.92 V on the gate and 12.5 V with 1.52 V on the gate. So when I see somewhere from 8 to 12 V on the drain, I know the capacitor has discharged to 1.5 to 2 VDC.

I set up a spreadsheet to figure resistance from V-initial, V-final, C and time 't', in seconds. Its uses the equation

R = -t / (C*ln(Vf / Vi))

Experiments

Turns out I don't actually have one of those anti-static pads but I do have some other stuff I wondered about. For one, those black foam rectangles you see ICs embedded in or affixed to, in the case of SMT. Another material is those shiny semi-transparent envelopes that the stuff we buy from Mouser or Digi-Key comes packed in.

I took a chunk of the black stuff, that used by AD to pack an AD9851 DDS chip in and stuck #18 solid wire electrodes in it lengthwise, about 1 inch apart and 1.5 inches deep and connected that across my capacitor. Connected the battery and then used a separate supply to charge the 0.22 uF capacitor to 10 VDC, at which time the drain voltage jumped from 12.5 VDC to 0 VDC. It took about 3 hours and 15 minutes for the voltage to start climbing and it quickly reached 11.8 VDC at 3 hours, 22 minutes. I inferred a gate voltage of ~1.85 volts from my earlier characterization of the 2N7000 and my spreadsheet spit out a value of 3.26E10 ohms, or 32.6 G-ohms between those electrodes.

Next I took one of those anti-static envelopes and inserted a couple pieces of circuit board material, about 1x2 inches as electrodes, spacing their long sides about 1/4 inch apart. So the conduction path is more or less across that 1/4 inch. I set a couple pieces of non-conductive "stuff" on top of the envelope to increase the contact area and started the timing thing again. This time it took 25 minutes & 22 seconds for the capacitor to discharge to the "threshold" region of about 1.9 V on the gate. The calculated resistance was 4.2E9 or 4.2 G-ohms. About one tenth of the reading with the black foam.

But it was interesting that I checked out a couple of other pieces of black spongy foam and measured resistances in the kilohms with my DMM, far too low to require my method.

My final experiment was a "control" test. The biggest resistor I have is marked 66 M-ohms at 10% tolerance. I connected it to the gizmo and saw the drain voltage quickly transition at 24 seconds. Spreadsheet says, 67.8 M-ohms. So I think the accuracy is pretty good.

In the interest of scientific rigor, I should say that I just arbitrarily measured the resistance between two points, or two electrodes. If I were being rigorous, I would have made things more complicated and attempted to measure volume or surface resistivity of the material. But my intent was just to answer the question, "I wonder what the resistance is between these two electrodes in or on this anti-static material?"

BTW, the 0.22 uF capacitor was just what I pulled out of the box. To keep the times from being excessively long, a capacitor an order of magnitude or so smaller would be a good idea, after verifying that its self discharge rate is appropriately long.

Nick, WA5BDU

3/27/2010

Here's an edit. It was suggested that a schematic would be a good idea, however simple this thing may be. I guess that's true:

So there's one. I charged C1 to 10 V to start the measurement, but there's no reason you couldn't just touch the battery positive to it to charge it. As long as you know the initial and final voltages, you're good. Another option would be to charge C1 to a value of the final target "threshold" voltage divided by 0.37. Since a capacitor will discharge to 37% of its initial voltage in one time constant, it simplifies the math of finding Rx. Like this -

tau = RC (tau is one time constant)

so, R = tau / C

3/28/2010

Saturday, February 27, 2010

2-meter FM receiver with MC3362 chip and Si570 synthesizer

Sunday, November 1, 2009

No-DDS DDS

A DDS using a PIC and a DAC chip ...

First, I apologize for having all the pictures piled up at the top. Someday I'll figure out how to insert them at the proper locations in the flow of the text.

Frequency synthesizers using the DDS (Direct Digital Synthesis) technique are lots of fun and I’ve built, let’s see … , four of them as stand-alone boards. I thought it would be fun to build one not by using an integrated DDS chip, but rather by using a microcontroller (PIC) and a DAC chip. Obviously I wouldn’t be achieving RF speeds, but this is just for the learning experience.

Within my PIC’s program, here’s the task at hand: The program runs in a loop that sends the proper voltage info (0 to 255) to the DAC each time through. One run through the loop always takes the same amount of time, 4 microseconds in my case. I want to produce a sine wave of a specified frequency. So I need to know, for each 4 microsecond advance in time, where I am in the 360 degree period of a sine wave of the desired frequency. Knowing that, I can look up the closest value of the sine wave in a table (there’s not enough time to calculate it) and put that out to the DAC. This is how any frequency up to the upper limit can be generated even though the loop is outputting numbers at a constant rate.

That upper limit is the based on sampling theory which says that with a minimum of two samples per cycle, the sine wave can be recovered. In practice a bit more than two is considered the actual limit. With my 4 u-sec loop time, I’d need 8 u-sec to send out two samples and my theoretical limit would be 1/8E-6 or 125,000 Hz.

The data (for a sine wave) is a 256 sample look-up table. Therefore, 256 = 360 degrees. For greater accuracy, 24 bits are used to allow a high precision phase increment.

The frequency of operation for the DDS is

f = PI*fclock/2^24 where fclock is the effective "frequency" of the program loop which is 1/T, where T is the time it takes to execute it, or 250,000 Hz in my case.

So, PI = f*2^24/fclock

I have to use the above to calculate a new PI every time I change the DDS output frequency. The PI is added to a phase accumulator in each passage through the loop. Since there are only 256 samples, only the most significant byte is examined to point to a sample in the table. Consider my 24-bit phase accumulator to be an integer plus fraction where the high byte (MSD) represents a full cycle (360 degrees) and the other 16 bits are fractional parts of a cycle.

To write the DDS loop, I need a 3-byte accumulator and a 3-byte PI. Calculation of the PI is done outside the loop, so assume it's known. Here's what the main loop does:

- Add the PI to the accumulator. The MSD will be the current phase angle of the sine wave to 8-bit accuracy. (MSD is the most significant digit, also known as the high byte of the 24-bit number.)

- Take the MSD of the accumulator and use it to look up the corresponding value of the sine wave in a table.

- Put that value out to the DAC

- Repeat

So the only bit of information supplied from outside the loop is the PI. When the external control routines want to change the frequency of the DDS, it just alters the PI.

Hardware details -

I decided to use a DAC chip I have in my junkbox, which is an AD7530 10-bit ADC. ($1.35 from B.G. Micro.) I'll tie the two highest bits to ground and my maximum output will be 1/4th of what it would be using all bits. Yes, I had enough bits in my calculation to use all 10, but that would make my update routine take longer and lower my maximum frequency.

I wasn’t sure how to apply this chip. The data sheet shows using an inverting op-amp on the output, which it appears is really necessary. This means I need a negative supply, unfortunately. Plus the chip needs +15V to power it. So now I need +15V, +5V (PIC) and negative for Vref. Vref can be positive or negative, but since the op-amp inverts it, I'm going with negative so I'll have a positive output. I'll also us the negative Vref on the negative op-amp supply so I won't require a rail-to-rail op-amp to get to 0 volts.

For the negative supply, I took a wall wart rated 9V at 200mA which puts out 14.5 V no load. Took that through 200W to a 10 V zener to get about -9.79 volts as a reference. Experimenting on a breadboard, I get +2.45 volts out with all 8 lines high, close to the expected value. The step is about 10 mV per bit. My op-amp is currently a 4558. It's GBP is over 3 MHz, but open loop gain goes from 100 dB at low frequency down to 30 dB at 100,000 Hz, so I'm not sure if it's fast enough or not.

The 2.45 volt maximum output might need a little boost, so I could use the other half of the 4558 for that, with a gain of 2.

I'll add a photo of the board here ...

Well, guess I can't add it here. Everything goes to the top it seems.

Schematic -

Which is no doubt going to happen to the schematic when I add it too ... I keep reading the "help" on this Google Blogger thing but it's not much help to me. But it's free and it works, to a degree.

Anyway, the schematic is in here somewhere. Mostly it's a connection diagram, but some details are presented in schematic form.

One of my favorite parts isn't part of the No-DDS at all but is the RS-232 to TTL interface. This is the two 2N7000 MOSFET circuits shown at the bottom. I've fooled with a lot of level translation circuits, especially the MAX232 chips and that family. I like this one because it uses a two dime active devices and two resistors and takes less connections than a MAX232, though to be fair, the chip does two conversions in each direction. One drawback of the circuit is that the signal out to the RS232 device doesn't go negative. Maybe I could have made that happen in the No-DDS circuit, since I do have negative voltage available.

Controlling it - the PC software interface ...

I needed a way to tell the PIC what frequency to generate, so I altered an old piece of DOS software I'd written earlier. A slight problem was in how to get the PIC's attention. The update loop needs to be as tight as possible, so it can't afford to poll for external input. The logical thing then is to use an interrupt. But I discovered that all the lines that were interrupt capable, I'd already used for I/O with the DAC. So I wondered if using the -MCLR line would work. This effectively forces the PIC to re-boot every time that line is actuated. It turned out to work OK. When the PC software wants to get the PIC's attention, it bangs the -MCLR line. The PIC restarts and part of the start-up code is for it to check its serial port for incoming data. That data will be the new PI, which will be stored before the PIC goes permanently (until the next restart) into the update loop.

I'm putting in a picture of the DOS screen. Some of the fields aren't used, since this program was developed to control full featured RF DDSs that were used as VFOs. I wrote this program in 8088/8086 assembly language using the A86 shareware assembler.

Conclusions

It worked pretty well. That rope-like waveform appearance was due to my scope acting up a bit. Like the 1-bit sine generator, I built this thing but am not sure why. I think I thought it would be fun, and I guess it sort of was. I combined a little electronics, a little PIC programming, and a little PC programming to produce a circuit that worked as imagined.

-Nick

Thursday, October 1, 2009

1-bit PIC sine wave generator

Sunday, September 27, 2009

My Nixie Clock